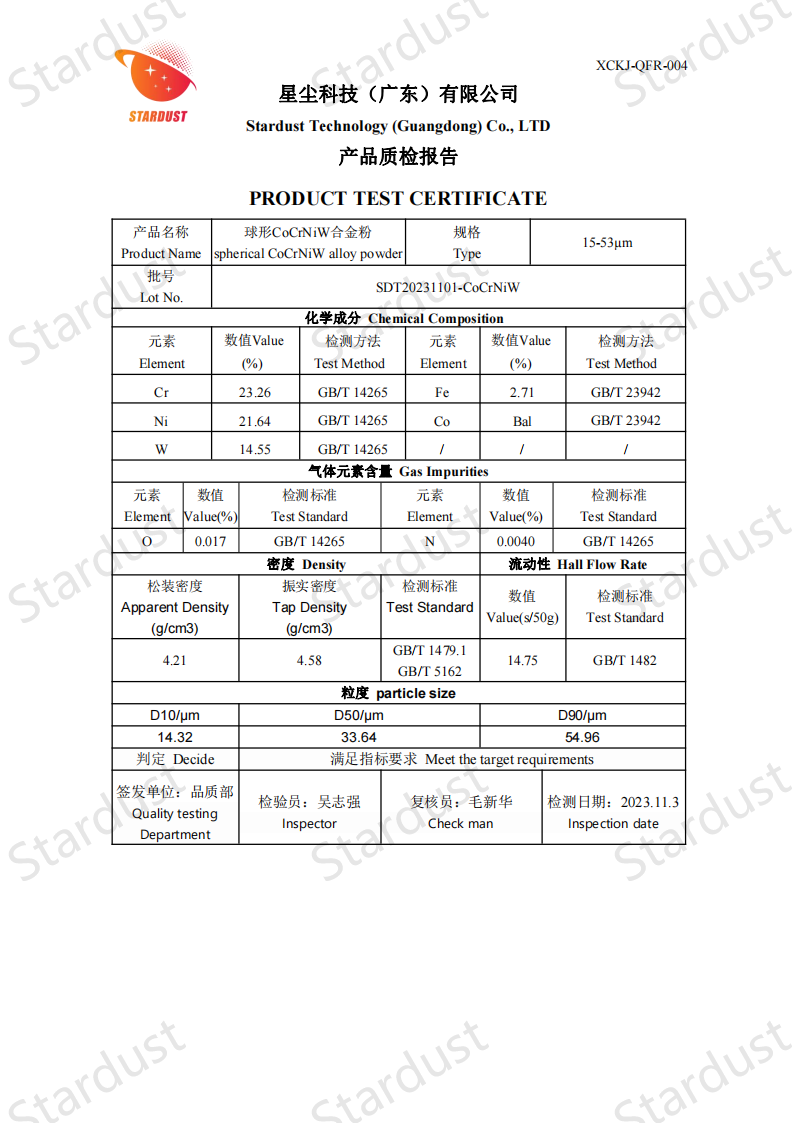

Spherical CoCrNiW alloy powder is composed of elements such as cobalt (Co), chromium (Cr), nickel (Ni) and tungsten (W), and has excellent high temperature stability, corrosion resistance and strong mechanical properties. The alloy powder is prepared by powder metallurgy process, the particles are spherical, have good fluidity and compactness, and are suitable for metal injection molding (MIM) and additive manufacturing (3D printing). Spherical CoCrNiW alloy powder is widely used in aerospace, automotive, military and other fields, especially in environments that need to withstand high temperature, strong corrosion and high load.

Item No :

Spherical CoCrNiW alloy powderOrder(MOQ) :

1kgProduct Origin :

Foshan City, Guangdong ProvinceLead Time :

3-7 days for spot goods; customized delivery time negotiated by both parties.Spherical CoCrNiW alloy powder is composed of elements such as cobalt (Co), chromium (Cr), nickel (Ni) and tungsten (W).

1. Characteristics

- Excellent high temperature performance: The alloy has good high temperature resistance, can maintain strong mechanical properties and stability in high temperature environment, and is suitable for applications under high temperature conditions.

- Corrosion resistance: The combination of elements such as chromium, cobalt and nickel gives the alloy excellent oxidation resistance and corrosion resistance, and can show strong corrosion resistance in harsh environments.

- High strength and hardness: The alloy powder has high hardness and strength, and can resist wear and deformation under high load and high stress.

- Good fluidity and compaction: Spherical particles have good fluidity and compaction, which is convenient for subsequent molding and processing.

2. Application fields

- Aerospace: Applicable to aircraft engines, gas turbines, nozzles and other components, which need to work under high temperature and high pressure environments. The high temperature strength and oxidation resistance of the alloy make it an ideal material.

- Automotive industry: used to manufacture high-performance engine parts, turbochargers and wear-resistant parts, capable of withstanding high temperature and high pressure operating conditions.

- Military field: The alloy is suitable for high-temperature parts in military equipment, such as missile engines, aircraft, etc., and can maintain good performance in extreme environments.

- Additive manufacturing and 3D printing: Due to the morphology of spherical particles, the alloy powder is suitable for additive manufacturing processes such as metal 3D printing and metal injection molding, and can produce complex shapes and high-performance metal parts.

3. Preparation method

- Radio frequency plasma spheroidization

Spherical cast tungsten carbide powder is a powder material with special morphology and properties. It is made of cast tungsten carbide through a special process. The powder is spherical and has the characteristics of uniform particle size distribution, good fluidity, high bulk density and tap density. Its chemical composition is mainly tungsten carbide (WC), which has the advantages of high hardness, high melting point, high wear resistance, and good chemical stability. It has a wide range of applications in metal processing, powder metallurgy, 3D printing, thermal spraying and other fields. It can be used to manufacture cutting tools, wear-resistant parts, coating materials, etc., which can significantly improve the performance and service life of related products.

Read More

Spherical cast tungsten carbide powder is a powder material with special morphology and properties. It is made of cast tungsten carbide through a special process. The powder is spherical and has the characteristics of uniform particle size distribution, good fluidity, high bulk density and tap density. Its chemical composition is mainly tungsten carbide (WC), which has the advantages of high hardness, high melting point, high wear resistance, and good chemical stability. It has a wide range of applications in metal processing, powder metallurgy, 3D printing, thermal spraying and other fields. It can be used to manufacture cutting tools, wear-resistant parts, coating materials, etc., which can significantly improve the performance and service life of related products.

Read More

Spherical nickel powder is a metal powder with a regular spherical appearance. Its main component is nickel. It has the characteristics of uniform particle size, large specific surface area, high activity and good conductivity. It has important applications in many fields such as battery materials, powder metallurgy, electronic paste, catalysts, etc.

Read More

Spherical nickel powder is a metal powder with a regular spherical appearance. Its main component is nickel. It has the characteristics of uniform particle size, large specific surface area, high activity and good conductivity. It has important applications in many fields such as battery materials, powder metallurgy, electronic paste, catalysts, etc.

Read More

Spherical cobalt powder is a metal powder with cobalt as the main component and a regular spherical shape. It has the characteristics of high purity, uniform particle size, large specific surface area, strong magnetism, and good catalytic activity. It is widely used in cemented carbide, magnetic materials, batteries, catalysts and other fields.

Read More

Spherical cast WC-Co powder is a common industrial material, often used to make carbide tools, drills, cutting tools, etc. This alloy is widely used in industrial manufacturing due to its high hardness, wear resistance and corrosion resistance.

Read More

Spherical copper powder is characterized by high purity, low oxygen content, high sphericity, smooth surface, no satellites, uniform particle size distribution, excellent flow properties, high bulk density and high vibration density.

Read More

Spherical IN625 powder is a kind of high-performance metal powder with excellent corrosion resistance, high strength and good high-temperature stability. It has uniform spherical particle size and is mainly composed of nickel, chromium, molybdenum and other elements. It is suitable for various advanced manufacturing processes such as laser additive manufacturing and thermal spraying. It is widely used in aerospace, petrochemical, energy and other fields.

Read More

IPv6 network supported

IPv6 network supported