Spherical Mo-40Re alloy powder is an alloy powder composed of molybdenum (Mo) and rhenium (Re), with a rhenium content of 40%. This alloy powder has excellent high temperature resistance, oxidation resistance and corrosion resistance, and is particularly suitable for more severe high temperature environments. The higher rhenium content enhances the strength and toughness of the alloy at high temperatures, making it widely used in aerospace, nuclear energy, electronic devices, and high temperature metallurgy. Its spherical powder morphology helps improve fluidity and formability, and is suitable for additive manufacturing and precision parts processing.

Item No :

Spherical Mo-40Re alloy powderOrder(MOQ) :

5kgProduct Origin :

Foshan City, Guangdong ProvinceLead Time :

3-7 days for spot goods; customized delivery time negotiated by both parties.Spherical Mo-40Re alloy powder is a high-performance alloy powder composed of molybdenum (Mo) and rhenium (Re) elements. Due to its high rhenium content, it has unique physical and chemical properties.

1. Characteristics

- High temperature performance: Mo-40Re alloy powder has very excellent high temperature strength and can maintain strong mechanical properties at extremely high temperatures. Molybdenum has a high melting point, while rhenium has an even higher melting point, so the high temperature strength of the alloy is significantly improved.

- Oxidation resistance and corrosion resistance: Rhenium has strong oxidation resistance and corrosion resistance, so Mo-40Re alloy powder has good stability in high temperature and corrosive environments.

- Radiation resistance: Due to the high proportion of rhenium in the alloy, Mo-40Re alloy powder has good radiation resistance in nuclear energy applications.

- Electrical conductivity and thermal conductivity: Similar to alloys of molybdenum and rhenium, Mo-40Re alloy powder has good electrical conductivity and thermal conductivity, and is suitable for some equipment that requires high electrical conductivity and high thermal conductivity.

- Hardness and mechanical properties: Mo-40Re alloy powder has high hardness, excellent wear resistance, can withstand high mechanical loads, and is suitable for high-strength applications.

2. Application fields

- Aerospace: Mo-40Re alloy powder is widely used in the aerospace field due to its excellent high-temperature performance and oxidation resistance, especially in spacecraft engines, jet propulsion systems and high-temperature components.

- Nuclear energy industry: Alloy powder plays an important role in nuclear energy applications, especially in the structural materials, fuel elements and radiation environments of nuclear reactors.

- Electronic and electrical industry: Mo-40Re alloy powder can be used to manufacture high-performance electrodes, connectors, resistors and other electronic components due to its good conductivity and heat resistance.

- High-temperature metallurgy and chemical industry: The alloy powder is also used in equipment, catalysts and chemical reactor components in high-temperature metallurgical processes, especially in extremely high temperature and corrosive environments.

- Automotive industry: In automotive turbochargers, exhaust systems and other high-temperature components, Mo-40Re alloy powder can provide excellent thermal stability and mechanical properties.

3. Preparation method

- RF plasma spheroidization

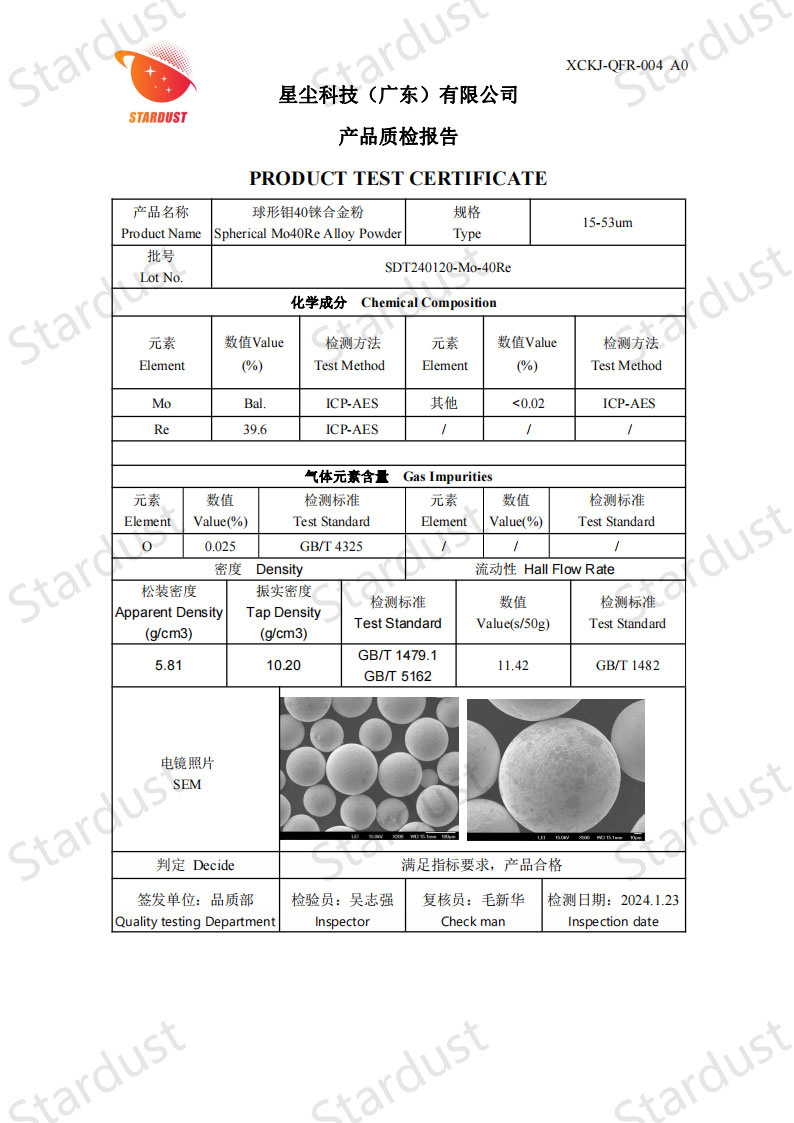

Spherical molybdenum powder is manufactured by radio frequency plasma spheroidization technology, with the characteristics of high purity, low oxygen content, high sphericity, smooth surface, no satellite, uniform particle size distribution, excellent flow performance, high bulk density and tap density.

Read More

Spherical molybdenum powder is manufactured by radio frequency plasma spheroidization technology, with the characteristics of high purity, low oxygen content, high sphericity, smooth surface, no satellite, uniform particle size distribution, excellent flow performance, high bulk density and tap density.

Read More

Spherical molybdenum powder is manufactured by radio frequency plasma spheroidization technology, with the characteristics of high purity, low oxygen content, high sphericity, smooth surface, no satellite, uniform particle size distribution, excellent flow performance, high bulk density and tap density.

Read More

Spherical molybdenum powder is manufactured by radio frequency plasma spheroidization technology, with the characteristics of high purity, low oxygen content, high sphericity, smooth surface, no satellite, uniform particle size distribution, excellent flow performance, high bulk density and tap density.

Read More

Spherical molybdenum powder is manufactured by radio frequency plasma spheroidization technology, with the characteristics of high purity, low oxygen content, high sphericity, smooth surface, no satellite, uniform particle size distribution, excellent flow performance, high bulk density and tap density.

Read More

Spherical molybdenum powder is manufactured by radio frequency plasma spheroidization technology, with the characteristics of high purity, low oxygen content, high sphericity, smooth surface, no satellite, uniform particle size distribution, excellent flow performance, high bulk density and tap density.

Read More

Spherical Mo-20Re alloy powder is an alloy powder composed of molybdenum (Mo) and rhenium (Re), which has excellent high temperature strength, oxidation resistance and corrosion resistance. Due to the addition of rhenium, the performance of the alloy in high temperature environment has been significantly enhanced, and it is particularly suitable for aerospace, nuclear energy, electronics and high temperature metallurgy. Its spherical powder morphology helps to improve fluidity and formability, and is often used in additive manufacturing and the production of high-precision parts.

Read More

Spherical Mo-20Re alloy powder is an alloy powder composed of molybdenum (Mo) and rhenium (Re), which has excellent high temperature strength, oxidation resistance and corrosion resistance. Due to the addition of rhenium, the performance of the alloy in high temperature environment has been significantly enhanced, and it is particularly suitable for aerospace, nuclear energy, electronics and high temperature metallurgy. Its spherical powder morphology helps to improve fluidity and formability, and is often used in additive manufacturing and the production of high-precision parts.

Read More

IPv6 network supported

IPv6 network supported