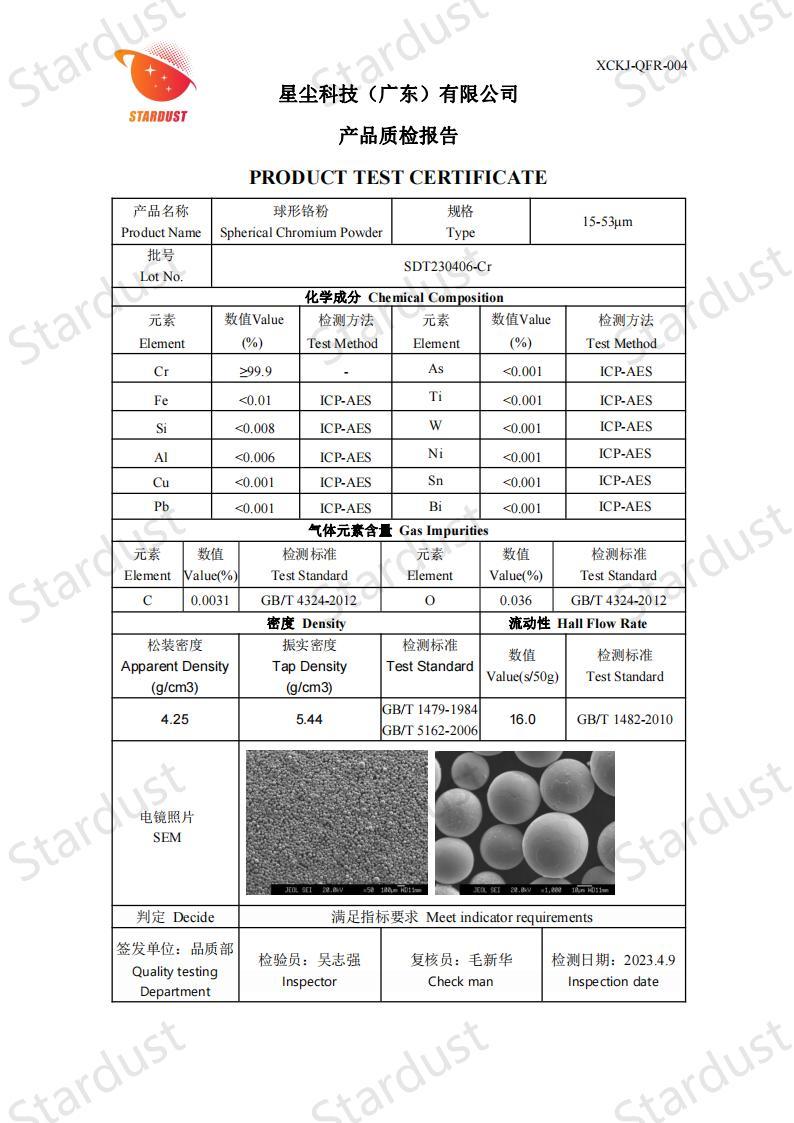

Spherical Cr powder is prepared by radio frequency plasma spheroidization technology, with high purity, low oxygen content, high sphericity, smooth surface, no satellite, uniform particle size distribution, excellent flow performance, high bulk density and tap density.

Item No :

Spherical Cr PowderOrder(MOQ) :

1 KgProduct Origin :

Foshan City, Guangdong ProvinceLead Time :

3-7 days for spot goods; customized delivery time negotiated by both parties.Spherical chromium powder is an important metal powder material with unique physical, chemical and mechanical properties, and is widely used in many fields.

1. Characteristics

1 High sphericity: Spherical chromium powder particles have regular shape and good fluidity, which is suitable for additive manufacturing and powder metallurgy.

2 High density: The density of chromium powder is high, providing good mechanical strength and wear resistance.

3 High melting point: The melting point of chromium is about 1907°C, which is suitable for high temperature application scenarios.

4 Good thermal conductivity: Chromium powder has high thermal conductivity and performs well in heat dissipation in high temperature environments.

5 Excellent corrosion resistance: Chromium forms a dense oxide layer at room temperature and has excellent corrosion resistance, especially in acidic and alkaline environments.

6 Antioxidation: At high temperatures, a stable oxide layer is formed on the surface of chromium powder, thus having good antioxidation properties.

7 Chemical stability: Chromium powder is stable in most chemical environments and is not easy to react chemically with other substances.

8 High hardness: Chromium powder has high hardness and is suitable for manufacturing wear-resistant parts.

9Good ductility: At high temperatures, chromium powder still maintains good ductility, which is convenient for processing complex shapes.

10High strength: Chromium powder has high mechanical strength and is suitable for high stress environments.

2. Application areas

1Additive manufacturing (3D printing)

-Metal 3D printing: Spherical chromium powder is used in metal 3D printing to manufacture parts with complex shapes, such as aerospace parts and medical devices.

-Rapid prototyping: Applied in rapid prototyping technology, it helps to shorten the product development cycle.

2Powder metallurgy

-Wear-resistant parts: Used to manufacture high-wear-resistant parts such as bearings, gears and cutting tools.

-Composites: Added as a reinforcing phase to metal-based composites, it can improve the strength and wear resistance of the material.

3Surface engineering

-Thermal spraying: In thermal spraying technology, spherical chromium powder is used to form a wear-resistant and corrosion-resistant coating on the surface of the substrate.

-Electroplating: Used in the electroplating process, it can improve the hardness and corrosion resistance of the metal surface.

4 Chemical Industry

- Catalyst: It can be used as a catalyst or catalyst carrier to participate in chemical reactions.

- Corrosion-resistant equipment: It is used to manufacture corrosion-resistant chemical equipment, such as reactors and pipelines.

5 Electronic Industry

- Electronic components: It is used to manufacture high-temperature electronic components, such as resistors and capacitors.

- Thermal management materials: It is used to make heat sinks and heat sinks to improve the heat dissipation performance of electronic equipment.

6 Nuclear Industry

- Nuclear reactor materials: It is used to manufacture key components in nuclear reactors, such as fuel cladding and heat exchangers.

- Radiation shielding: It is used to manufacture radiation shielding materials to provide good radiation protection performance.

3. Preparation method

RF plasma spheroidization method

Spherical Cr powder is prepared by radio frequency plasma spheroidization technology, with high purity, low oxygen content, high sphericity, smooth surface, no satellite, uniform particle size distribution, excellent flow performance, high bulk density and tap density.

Read More

Spherical Cr powder is prepared by radio frequency plasma spheroidization technology, with high purity, low oxygen content, high sphericity, smooth surface, no satellite, uniform particle size distribution, excellent flow performance, high bulk density and tap density.

Read More

Spherical Cr powder is prepared by radio frequency plasma spheroidization technology, with high purity, low oxygen content, high sphericity, smooth surface, no satellite, uniform particle size distribution, excellent flow performance, high bulk density and tap density.

Read More

Spherical Cr powder is prepared by radio frequency plasma spheroidization technology, with high purity, low oxygen content, high sphericity, smooth surface, no satellite, uniform particle size distribution, excellent flow performance, high bulk density and tap density.

Read More

Spherical Cr powder is prepared by radio frequency plasma spheroidization technology, with high purity, low oxygen content, high sphericity, smooth surface, no satellite, uniform particle size distribution, excellent flow performance, high bulk density and tap density.

Read More

IPv6 network supported

IPv6 network supported