Item No :

Spherical Ta-5.5W Alloy PowderOrder(MOQ) :

1 kgProduct Origin :

Foshan City, Guangdong ProvinceLead Time :

3-7 days for spot goods; customized delivery time negotiated by both parties.Spherical Ta-5.5W alloy powder

I. Characteristics

1. High melting point: The melting point of tantalum (Ta) is about 3017°C. Ta-5.5W alloy inherits the high melting point characteristics of tantalum and is suitable for extreme high temperature environments.

2. Excellent corrosion resistance: Ta-5.5W alloy exhibits extremely strong corrosion resistance in acids (such as hydrochloric acid, nitric acid, sulfuric acid) and most chemical media.

3. Good mechanical properties: Ta-5.5W alloy has high strength (tensile strength of about 500-700 MPa) and good ductility.

4. High temperature stability: It can still maintain good mechanical properties and oxidation resistance in high temperature environments (below about 1600°C).

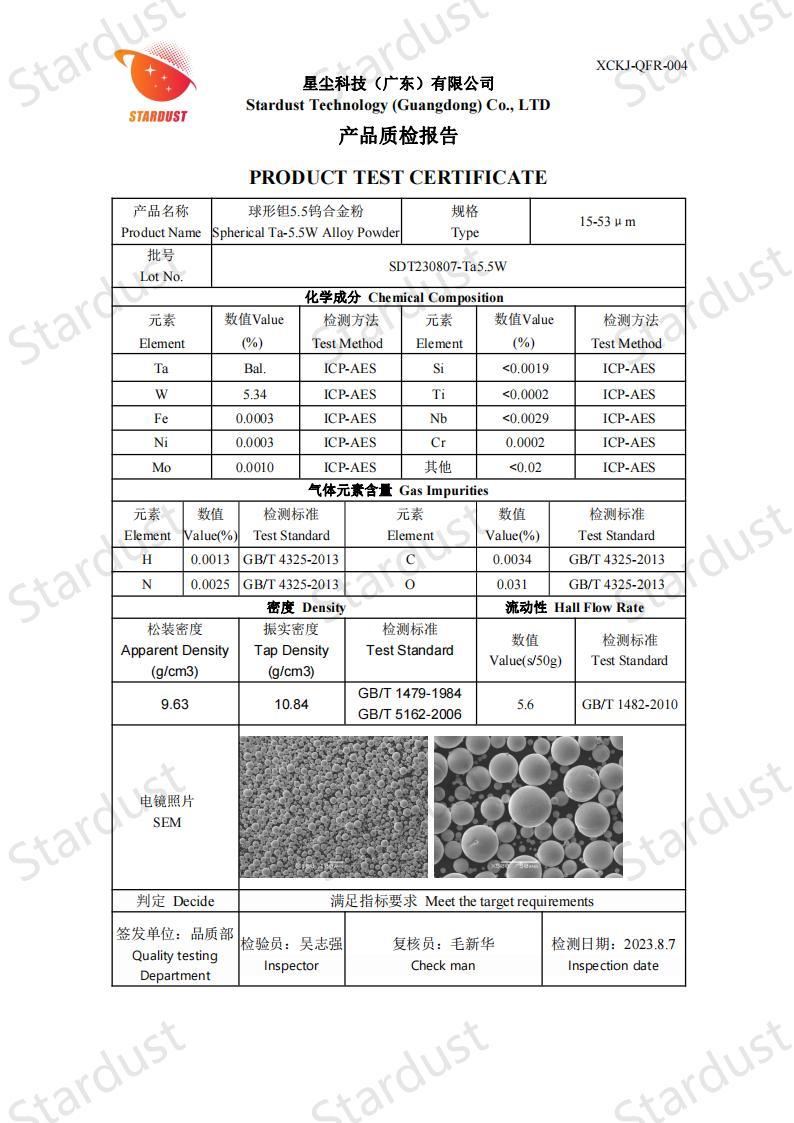

5. Spherical particle morphology: Spherical Ta-5.5W alloy powder has good fluidity and is suitable for additive manufacturing and powder metallurgy processes.

II. Application fields

1. Chemical industry: used to manufacture corrosion-resistant reactors, heat exchangers and pipelines.

2. Aerospace: used to manufacture high-temperature structural parts, rocket engine components and thermal protection materials.

3. Electronic industry: used to manufacture heat-resistant parts in high-temperature electronic components and semiconductor equipment.

4. Nuclear industry: used to manufacture high-temperature parts and corrosion-resistant materials in nuclear reactors.

5. Additive manufacturing (3D printing): used to manufacture high-temperature and corrosion-resistant parts of complex structures.

III. Preparation method

RF plasma spheroidization method